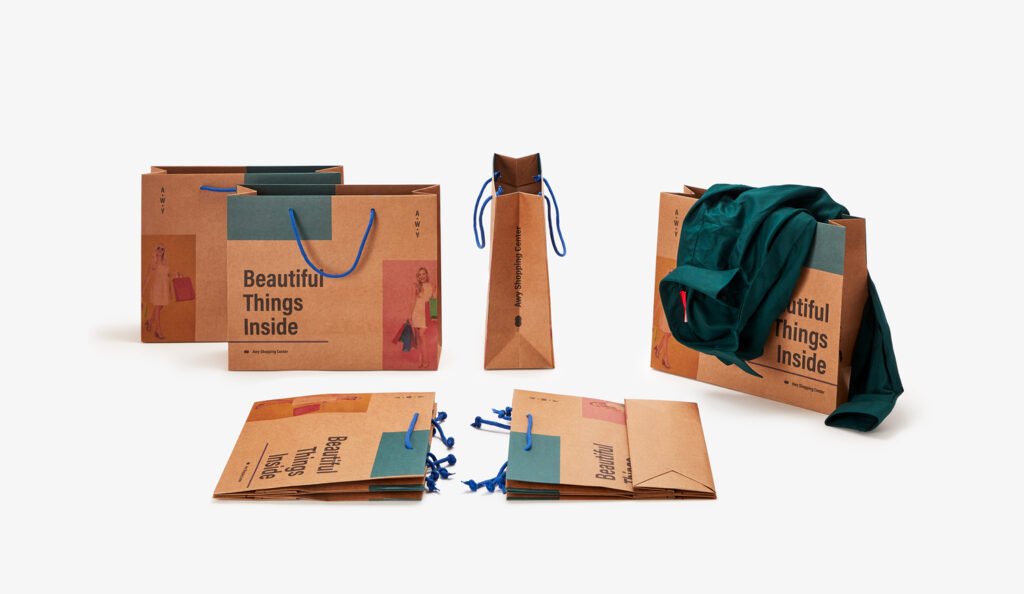

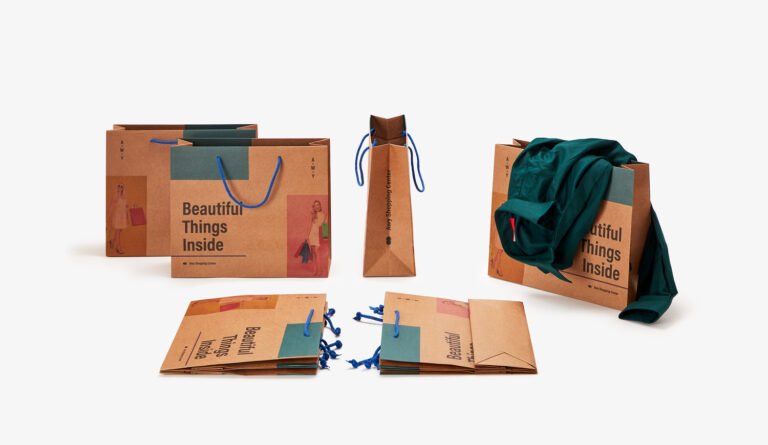

Wondering whether your business should start using paper bags?If your answer is positive, then there are several advises for you to make a good decision.

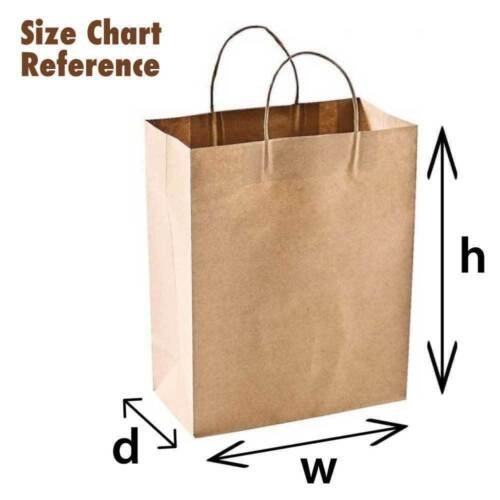

1. Dimension:The Primary Elements for Bags Customization

Size: n is one of the main decision for the cost. Small bags cost less than large ones because of the production materials and shipping cost.

You can decide the bag specification by your own product size before asking for a quote. Also, you can get a dimension reference chart from service staffs of Iwpak and make a decision on the final size.

2. Quantity: The More You Order, The More You Will Save.

Paper bags which are common in everyday life needs to go through many complicated stages such as design, layout, mold making, product printing, folding, sticking, punching eyelet holes (if any), making straps, and other techniques, including metal pressing, hot-stamping, embossing, UV/vanish coating, laminating, glossy film, and so on.

The more quantity of paper bags you order, the lower cost will be. Since in the manufacturing process, factories will reduce the cost of compensation, saving time to prepare the machine and human source.

Therefore, if you want to get a better price, you have to order as more as possible.

3. Color: Another Importing Factor on Price.

The price of a paper bag depends on the number of colors you want to print, including special requirements such as metallic color. For Example, a monochrome color logo always costs less than a logo that requires complex tinting techniques.

Moreover, CMYK printing will be cheaper than the spot color printing, and the computer printing is more expensive than the digital printing.

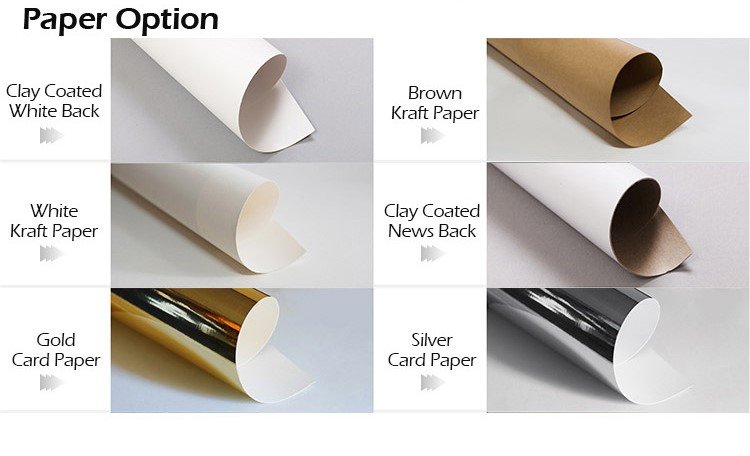

4. Paper Material: Three Types You Should Know

A premium, affordable paper bag depends heavily on the material and paper weight. This is not only aesthetic but also determines the bearing capacity, toughness, durability of paper bags when containing products inside.

There are 3 types of favored paper:

①Bleached White or natural brown Kraft paper, quantitative 120 – 160 gsm:

Kraft paper is uncoated so it feels natural, rustic, and friendly. You will see this type of paper bag is often printed with the twisting string or folded paper rope. It is important to note that a hand-made paper bag manufacturer might push for a 120+ gsm product, this is because it is easier to die-cut thicker paper.

②White/Black Cardboard Paper Bags, whose thickness at around 210~280gsm:

For the cardboard bags, 230gsm is wildly used thickness. Application is including the clothes&shoe physical store, gift shops and company enterprise propagates. White bags are normally coated coated with the glossy or matt lamination which can prevent smudge and make bags more durable.

It should be noted that the black cardboard bags who is black inside and outside, cannot be laminated, and feels not smooth as the white cardboard bags. It often use cooperatively with the stamping craft in order to upgrade the packaging quality.

③Recycled white, brown or printed paper:

As same as other uncoated papers, recycled paper is recycled from used paper, so this is an environmentally friendly option, which is gradually becoming a common trend. If your company’s standpoint is on the issue of environmental protection. The the shopping bags made of recycled paper will be your first choice.

5. Handles Rope: Know More about the Accessories

There are countless different types of paper bag straps, depending on the size, paper type and design.

①Twisted straps

This type of strap is usually simple, with good strength and high economic efficiency. Made from 100% recyclable materials, it is also environmentally friendly. This bag has the option of brown, white or printed according to the color of the bag – available in standard or advanced ranges.

②Rope straps

Rope paper bag straps made from cotton or PP. This type of strap is simple, softer than twisted paper straps, and is at an affordable cost.

**How to fix the string into eyelet hole?

– T-lace(Shoe buckle Ended): You can make plastic shoe buckle in the same colors with two ends of the same color with the string to create a unified whole (normally the black is default). Using T-lace prevent the pocket strap from sliding from the eyelet is the simplest way.

– Knot: Instead of plastic T-lace, you can also fix it with a knot. Compared with T-lace, this method takes more time to finish so the price is also higher. However, it is suitable for handmade products.

③Die-cut

A very popular type of handleless bag strap is the die-cut, which will be created during the die-making process. Die-cut paper bags are modern and easily stored in shops.

④Ribbon straps

Ribbon straps have never been unpopular because of its convenience: diverse colors, flexible for logos and brand slogan. Ribbon straps are suitable for high-end paper bags thanks to their softness, increasing the attractiveness of paper bags.

To secure the ribbon straps, paper bags manufacturer will not use T-laces or knots, but hide it on the inside edge of the bag. This contributes to the increased elegance and style inherent in high-end paper bags. Certainly, it takes more time and cost.

6. Lamination:To Make the Bags More Durable

Lamination is a method of laminating a thin layer of plastic onto paper to protect the printing surface. Laminating helps the luxury paper bag be more tear resistant, water resistant and more reusable.

Lamination is generally divided into two types: glossy lamination and matt lamination.

Gloss film suitable for high-class paper bags needs sharpness and clarity of every detail, creating a sense of health and modernity.

Matt lamination is suitable for paper bags that need to show softness and elegance.

Both methods prevent the bags from dirt, smudges or fingerprints.

7. Techniques: Finishing Touch on Your Bags

To make the paper bag look more eye-catching, attractive and more advanced, you can add some of the following techniques:

Print inside the bag: The inside of a standard bag is usually white or the color of paper. It would be great if you want the bag to stand out, more unique by printing more details or array of colors in inside the bag.

UV/vanish coating is perfect if you want to emphasize or highlight a part of a paper bag, usually a logo, slogan or design details.

Embossing is a method that makes a detail on the paper bag concave or convex compared to the paper surface, forming sophisticated 3D blocks for the product.

Pressing(Texture Graining) is the most popular choice, especially for high-class bags of wine, watches, jewelry. The yellow/white color of the emulsion gives a premium look to the product.

Once you understand all of the options above, you can confidently order them at a paper bag manufacturing company (like IWPAK). Also, if you still have questions or need clear advice at a certain step, we are here to help you.

Iwpak- The one-stop online store for all your design and printing needs, including paper bags, poly mailers, wrapping paper, business cards, brochures, flyers and so on. We always offer our customers the highest quality and most affordable printing and design services, without ever compromising on the quality of the materials and service.

Cosima